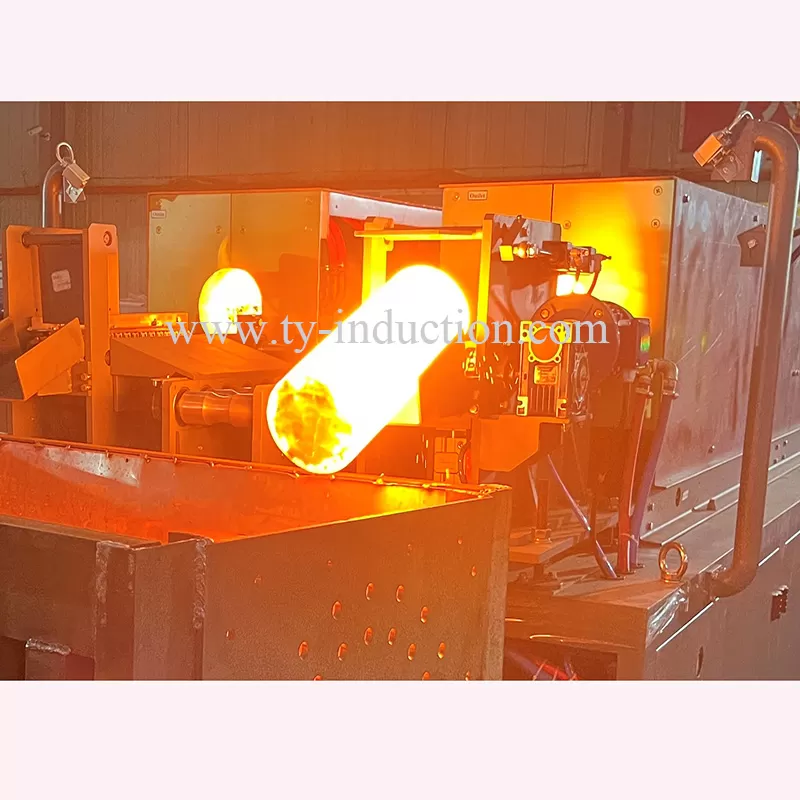

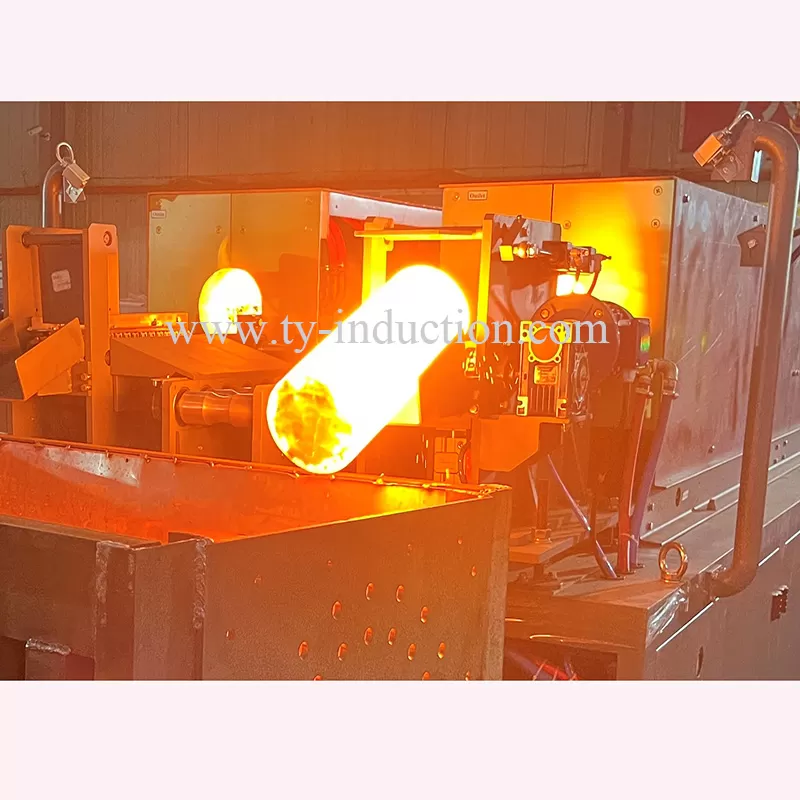

In the dynamic realm of metalworking, efficiency, precision, and cost-effectiveness are paramount. Induction heating stands out as a revolutionary technology, redefining the landscape of forging processes. As industry leaders, we understand the pivotal advantages that induction heating brings to the table, making it an indispensable tool for modern forging operations.

Harnessing the Power of Induction Heating

Swift Heating with Pinpoint Accuracy

Induction heating relies on electromagnetic fields to generate heat directly within the material. This results in rapid and precise heating, avoiding unnecessary energy wastage. Traditional methods pale in comparison, often leading to uneven heating and prolonged processing times.

Enhanced Control for Complex Shapes

One of the standout advantages is the ability to tailor the heating process according to the specific geometry of the metal piece. Unlike conventional methods, induction heating ensures uniform temperature distribution, allowing for the forging of intricate shapes without compromising structural integrity.

Efficiency Redefined

Reduced Energy Consumption

In an era where sustainability is non-negotiable, induction heating emerges as an eco-friendly alternative. The direct application of heat minimizes energy loss, translating to lower power consumption compared to conventional furnaces. This not only aligns with environmental goals but also contributes to substantial cost savings.

Faster Processing Equals Increased Productivity

Time is money, especially in the manufacturing sector. Induction heating's rapid heating capabilities significantly reduce processing times, enabling quicker turnaround for forging operations. This increased efficiency directly translates to heightened overall productivity and, consequently, a competitive edge in the market.

Precision Forging, Every Time

Consistent Quality Across Batches

Quality control is the bedrock of any forging process. Induction heating ensures that each piece undergoes uniform heating, minimizing the risk of defects or inconsistencies. This level of precision is challenging to achieve with traditional heating methods, where variations in temperature can compromise the structural integrity of the final product.

Minimized Material Waste

Precision in heating means minimized material waste. Traditional methods often lead to overconsumption of resources due to uneven heating, resulting in excess material being discarded. Induction heating, with its targeted approach, optimizes material usage, contributing to a more sustainable and cost-effective manufacturing process.

The Economic Edge

Cost-Effective Maintenance

Induction Heater for Forging boast a longer lifespan and require less maintenance compared to traditional furnaces. This translates to reduced downtime and lower maintenance costs, providing a clear economic advantage for businesses investing in this cutting-edge technology.

Adaptability to Various Materials

Whether you're working with steel, aluminum, or other alloys, induction heating proves its versatility. The technology is not bound by the limitations that traditional furnaces often face, allowing for seamless adaptation to different materials and ensuring a broader spectrum of applications.

Embracing the Future of Forging

In conclusion, the advantages of using Induction Forging Machine are not merely incremental; they are transformative. The combination of swift, precise heating, enhanced efficiency, and cost-effectiveness positions induction heating as the undisputed leader in the forging industry.

As industries evolve, embracing innovative technologies becomes imperative for staying ahead of the curve. Induction heating is not just a tool; it's a catalyst for progress, redefining the very foundations of metal forging. To remain competitive and ensure the highest standards in your forging processes, making the switch to induction heating is a strategic move that promises lasting dividends.

Comments

Please Join Us to post.

0