Are you a coffee enthusiast looking to streamline your packaging process? Have you ever wondered how the perfect amount of coffee ends up in those neatly sealed bags? If so, you've come to the right place! In this comprehensive guide, we will explore the world of coffee weighing packaging machines.

Introduction

Coffee is more than just a beverage; it's a daily ritual for millions of people worldwide. Whether you run a small coffee shop or a large-scale coffee production facility, ensuring the right amount of coffee goes into each package is crucial for quality and customer satisfaction.

The Importance of Precision

Imagine opening a bag of coffee, only to find it's either half empty or overflowing. Precision in coffee packaging is vital to maintain product consistency and meet customer expectations. This is where coffee weighing packaging machines come into play.

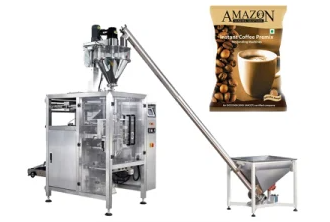

How Coffee Weighing Packaging Machines Work

These machines utilize cutting-edge technology to measure and dispense coffee accurately. They employ a combination of sensors, scales, and conveyor systems to ensure each bag receives the perfect amount of coffee grounds.

Types of Coffee Weighing Packaging Machines

Coffee weighing packaging machines come in various types, including volumetric fillers, gravimetric fillers, and auger fillers. Each type has its unique advantages and is suitable for different coffee products.

Advantages of Using Coffee Weighing Packaging Machines

Consistency: These machines ensure each bag has the same weight, maintaining product quality.

Efficiency: Coffee packaging is faster and more efficient, increasing production rates.

Reduced Waste: Precise measurements reduce coffee wastage, saving costs.

Customization: Machines can be adjusted for various bag sizes and coffee types.

Choosing the Right Machine for Your Business

Selecting the right coffee weighing packaging machine depends on factors such as your production volume, budget, and packaging requirements. It's essential to research and consult with experts to make an informed decision.

Maintenance and Care

To keep your machine running smoothly, regular maintenance is crucial. Cleaning, calibration, and part replacement when necessary will extend the machine's lifespan and ensure consistent performance.

Cost Considerations

While coffee weighing packaging machines can be a significant investment, they pay off in the long run through increased efficiency and reduced waste. Calculate the ROI for your specific business needs.

Conclusion

In conclusion, coffee weighing packaging machines are indispensable tools for coffee producers and businesses of all sizes. They guarantee precision, efficiency, and consistency in coffee packaging, ultimately leading to satisfied customers and increased profitability.

Personal Touch: My Coffee Packaging Journey

I've been in the coffee industry for over a decade, and I've seen firsthand how coffee weighing packaging machines revolutionized the way we package our beans.

Actionable Suggestions for Coffee Packaging

Here are some actionable suggestions to optimize your coffee packaging process:

Regular Maintenance: Schedule routine maintenance to ensure your machine operates at its best.

Employee Training: Train your staff to operate the machine efficiently and troubleshoot common issues.

Quality Control: Implement strict quality control measures to ensure every bag meets your standards.

Steps to Implement Coffee Weighing Packaging

Assess Your Needs: Determine your packaging volume and budget.

Research: Explore the different types of coffee weighing packaging machines available.

Consult Experts: Seek advice from industry experts to make an informed decision.

Purchase and Install: Acquire the chosen machine and install it in your production line.

Regular Maintenance: Schedule regular maintenance to keep the machine in optimal condition.

Ready to enhance your coffee packaging process? Explore our range of coffee weighing packaging machines and take your coffee business to the next level.

Comments

Please Join Us to post.

0