Efficient packaging is crucial for businesses in today's competitive market. It not only ensures the safe transportation of goods but also contributes to cost savings and customer satisfaction. When it comes to corrugated packaging, the 5 Ply Corrugated Machine has emerged as a potential game-changer. This article explores whether the 5 Ply Corrugated Machine is the key to boosting packaging efficiency and how it can revolutionize the industry.

Understanding the 5 Ply Corrugated Machine:

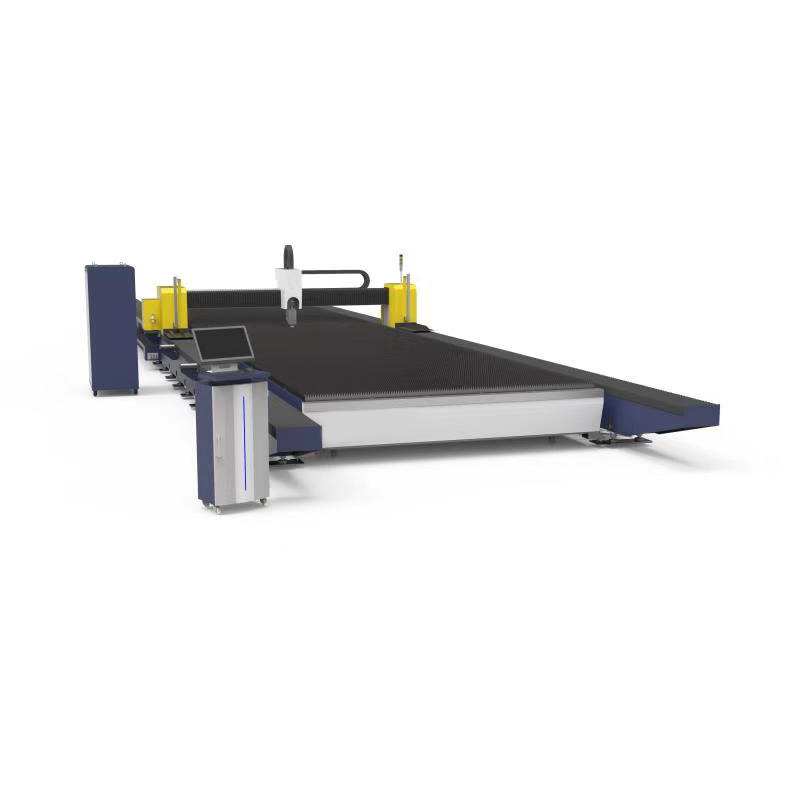

The 5 Ply Corrugated Machine is an advanced packaging solution that specializes in producing high-quality corrugated boards. It utilizes a combination of layers, typically five, to create a sturdy and durable material suitable for various packaging applications. The machine's core components include a reel stand, corrugating rolls, glue unit, preheater, single facer, slitter scorer, and cutoff unit, working seamlessly together to manufacture corrugated boards.

Enhancing Packaging Efficiency:

Increased Strength and Protection: The 5 Ply Corrugated Machine produces corrugated boards with multiple layers, offering enhanced strength and protection for packaged goods. The additional layers increase the overall rigidity, making it ideal for transporting fragile or heavy items without the risk of damage.

Customizability and Versatility: This machine provides flexibility in terms of board thickness, flute profiles, and dimensions. It allows businesses to create customized corrugated boards tailored to their specific packaging requirements. From simple shipping boxes to intricate display packaging, the 5 Ply Corrugated Machine enables versatility in design and functionality.

Streamlined Production Process: The machine integrates various components and processes into a streamlined production line, reducing manual labor and increasing overall productivity. With its automated features, such as precise control of glue application, consistent flute formation, and accurate cutting, it ensures high-quality and efficient board production.

Explore more:Rotary Drilling vs. DTH Drilling: Understanding the Key DifferencesMobile Tower Crane: Revolutionizing Construction LiftingUnderstanding the Difference Between AWP and EWPWhat is the Difference Between AWP and EWP?Enhancing Efficiency and Performance with a Horizontal Slurry PumpHorizontal Flow Wrap Machine: Enhancing Packaging Efficiency and ProductivityWhat is the closing time for an annular BOP?

Waste Reduction: The 5 Ply Corrugated Machine optimizes material usage by minimizing waste. Its advanced design and precise control mechanisms help in achieving precise cuts and minimizing excess material, resulting in cost savings and environmental benefits.

Considerations for Implementing the 5 Ply Corrugated Machine:

Initial Investment: Investing in a 5 Ply Corrugated Machine requires careful consideration of costs, including the machine itself, installation, maintenance, and staff training. However, the long-term benefits and improved efficiency can offset the initial investment.

Production Volume: Evaluate your packaging needs and production volume to determine if the machine's capacity aligns with your requirements. It is essential to choose a machine that can handle your anticipated output while maintaining consistent quality.

Operator Training and Maintenance: Proper training for machine operators is crucial to maximize efficiency and avoid operational issues. Additionally, regular maintenance and servicing of the machine are necessary to ensure optimal performance and longevity.

Conclusion:

Efficient packaging plays a significant role in optimizing supply chain operations, reducing costs, and satisfying customers' expectations. The 5 Ply Corrugated Machine offers promising solutions to enhance packaging efficiency. With its ability to produce high-quality corrugated boards, customizable design options, streamlined production processes, and waste reduction capabilities, this machine has the potential to revolutionize the packaging industry. However, it is crucial for businesses to carefully assess their specific needs, consider the investment and production volume, and ensure proper training and maintenance to fully harness the benefits of the 5 Ply Corrugated Machine. By implementing this advanced packaging solution, businesses can boost their packaging efficiency and gain a competitive edge in the market.

Explore more:Automatic Screw Driving Machine: Efficient and Reliable Automation SolutionScrewdriving Robot: Revolutionizing Industrial AutomationHow does oil extraction machines work?Inline Plastic Scrap Granulator: A Revolutionary Solution for Plastic Waste RecyclingX-ray Counter: Revolutionizing Medical ImagingEnhancing Efficiency and Precision: The Advantages of CNC Pipe Threading LathesUnderstanding the Pricing Factors of Portable Pipe Cutting Machines

Comments

Please Join Us to post.

0