Introduction

In today's advanced manufacturing landscape, precision is paramount. When it comes to creating intricate parts and components with exceptional accuracy, CNC milling services have become an indispensable solution. Computer Numerical Control (CNC) milling utilizes automated machinery to precisely shape and cut various materials, enabling the production of complex and customized parts. In this article, we will explore the world of CNC milling services, examining its advantages, applications, and how it can meet your unique manufacturing requirements.

What is CNC Milling?

CNC milling is a manufacturing process that utilizes computer-controlled machinery to remove material from a workpiece, creating a desired shape or form. The process involves a milling machine equipped with rotating cutting tools, guided by a computer program to perform precise operations with speed and accuracy.

Advantages of CNC Milling Services

CNC milling offers numerous advantages that make it a preferred choice for precision manufacturing:

1. Precision and Accuracy

CNC milling machines are capable of achieving remarkable precision and accuracy, often within micrometer tolerances. The computer-controlled automation ensures consistent and repeatable results, eliminating human error and delivering parts with exceptional dimensional accuracy.

2. Versatility

CNC milling services are highly versatile and can work with a wide range of materials, including metals, plastics, composites, and more. Whether you need to create complex 3D shapes, intricate patterns, or detailed engravings, CNC milling machines can handle various materials with ease, opening up a world of possibilities for your manufacturing needs.

3. Efficiency and Speed

CNC milling processes are known for their efficiency and speed. Once the computer program is set up, the milling machine can operate continuously, maximizing productivity. The automation reduces setup times and minimizes idle periods, ensuring efficient use of time and resources.

4. Complex and Customized Designs

Explore more:Ultimate Guide to Gravel Screen Mesh: Answers to Your Top QuestionsHow to Choose the Best CNC Tool Holder?Discover Top Tips for Buying Used Hydraulic Gate ValvesTop Temporary Electric Fence for Cattle: Ultimate Solution for Fencing NeedsAluminum Telescopic Pole: A Versatile Tool for Height Access and VersatilityApplications of Non-Metallic Flexible Conduit FittingsThe Most Precise Metal Casting: Achieving Unparalleled Accuracy in ManufacturingCNC milling services excel in producing complex and customized designs that would be challenging or impossible to achieve with traditional manufacturing methods. The ability to precisely control the cutting tools allows for intricate details, fine finishes, and unique geometries, enabling the creation of highly customized parts and components.

5. Cost-Effective Manufacturing

While CNC milling may involve an initial investment in machinery and programming, it offers long-term cost savings. The automated nature of the process reduces labor costs and minimizes material waste. Additionally, CNC milling machines are capable of producing parts with high precision, reducing the need for post-machining operations and saving time and resources.

Applications of CNC Milling Services

CNC milling services find applications in a wide range of industries and sectors, including:

Aerospace and Defense: CNC milling is vital in the production of aerospace components, such as engine parts, structural components, and intricate aircraft interiors.

Automotive: The automotive industry utilizes CNC milling for the manufacturing of engine blocks, transmission components, chassis parts, and custom automotive accessories.

Medical and Healthcare: CNC milling plays a crucial role in producing medical devices, implants, surgical instruments, and prosthetics with high precision and biocompatibility.

Electronics: CNC milling is utilized in the production of printed circuit boards (PCBs), electronic enclosures, connectors, and other intricate components used in the electronics industry.

Prototyping and Product Development: CNC milling services are instrumental in rapid prototyping and product development, allowing for the creation of functional prototypes, iterative designs, and small production runs.

Conclusion

CNC milling services have revolutionized the world of precision manufacturing. With their unmatched precision, versatility, and efficiency, CNC milling machines provide a reliable solution for creating complex and customized parts and components. The ability to achieve exceptional accuracy, along with the cost-effective nature of the process, makes CNC milling an attractive choice for various industries.

Whether you require intricate aerospace components, customized automotive parts, or high-precision medical devices, CNC milling services offer the capabilities to bring your unique designs to life. Embrace the power of CNC milling and unlock the potential for precision manufacturing that meets the demands of the modern world.

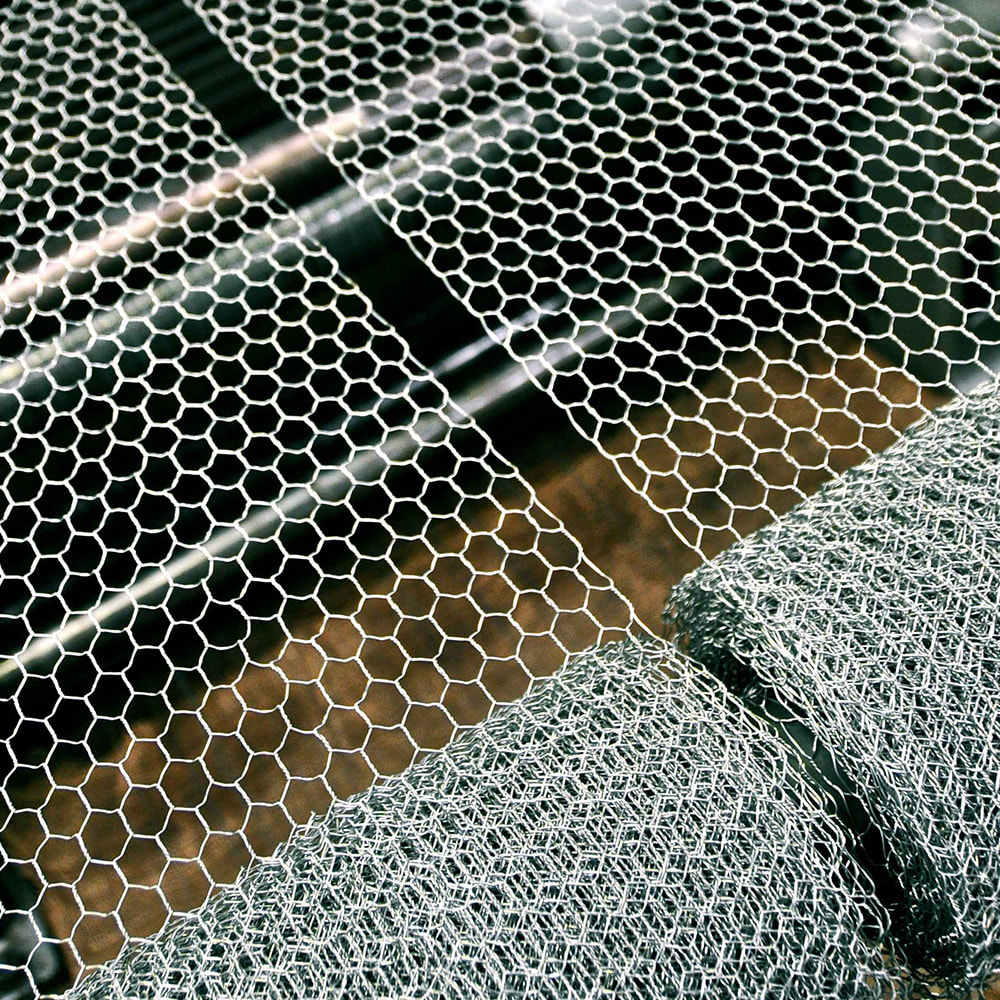

Explore more:The Essential Guide to Roller Bearing Applications: Maximizing Efficiency and PerformanceWhat Are The Key Design Considerations for Plastic Injection Molding?What are the common aluminum extrusion profiles?The Electric Actuator: Revolutionizing AutomationShandong NiuShang Auto Parts Co., Ltd participated in the Iran (Tehran) International Auto Parts ExhibitionHexagon Metal Mesh: Applications and Benefits8 Different Types of Water Valves Used in Home Plumbing

Comments

Please Join Us to post.

0