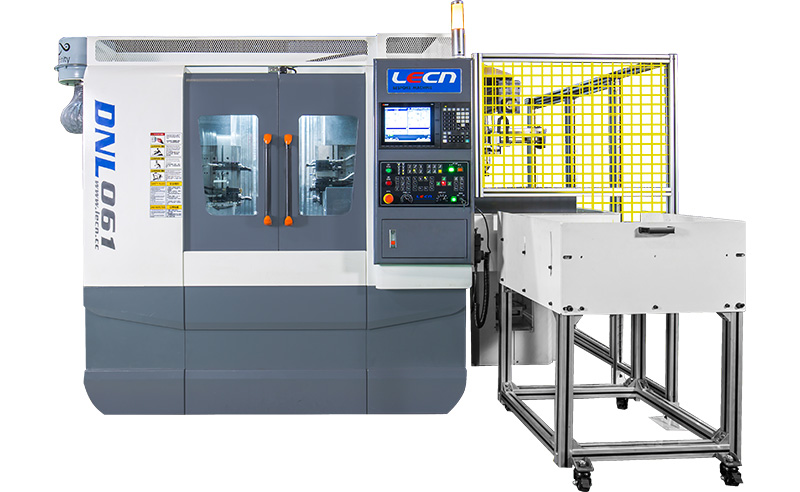

Double head CNC lathes are advanced machining tools that offer increased efficiency and productivity compared to their single head counterparts. These machines are equipped with two independent machining heads that can simultaneously work on a single workpiece, reducing cycle times and maximizing output. By leveraging the power of automation and precision control, double head CNC lathes have transformed the landscape of precision machining.

Understanding CNC Lathe Technology

Before delving into the specifics of double head lathes, let's first understand the basics of CNC lathe technology. CNC (Computer Numerical Control) lathes are automated machines that use computer programming to control the movement and operation of cutting tools. These machines are capable of performing a wide range of machining operations, such as turning, facing, drilling, and threading, with exceptional precision and repeatability.

CNC lathes utilize various axes, including X, Y, and Z, to control the movement of the cutting tools and workpiece. The programming language, often based on G-code, instructs the machine on the specific operations to be performed, the tooling paths, and the cutting parameters. With the advent of double head CNC lathes, manufacturers can now achieve even higher levels of efficiency and productivity.

The Advantages of Double Head CNC Lathes

Double head CNC lathes offer several significant advantages over traditional single head lathes, making them a preferred choice for precision machining. Here are some key benefits:

a. Increased Productivity

With two independent machining heads, double head CNC lathes can work on multiple features of a workpiece simultaneously. This parallel machining capability significantly reduces cycle times, allowing for faster production and increased throughput. By eliminating the need for multiple machine setups or manual intervention, double head CNC lathes optimize manufacturing processes and enhance productivity.

b. Improved Accuracy and Repeatability

Double head CNC lathes employ advanced control systems and precision mechanisms to ensure exceptional accuracy and repeatability in machining operations. The synchronized movement of the two machining heads guarantees precise alignment and dimensional consistency. This level of precision is especially critical for industries that require tight tolerances and high-quality finished products.

c. Versatility and Flexibility

Custom Double head CNC lathes offer enhanced versatility, allowing manufacturers to machine complex workpieces with various features and geometries. The ability to perform multiple operations simultaneously eliminates the need for separate setups, reducing the chances of errors and improving overall process efficiency. This versatility makes double head CNC lathes suitable for a wide range of industries and applications.

d. Cost Savings

While the initial investment in a double head CNC lathe may be higher than a single head lathe, the long-term cost savings can be significant. The increased productivity and reduced cycle times achieved with double head CNC lathes translate into higher production output and reduced labor costs. Additionally, the precise control and repeatability minimize material waste and rework, further contributing to cost savings.

Comments

Please Join Us to post.

0