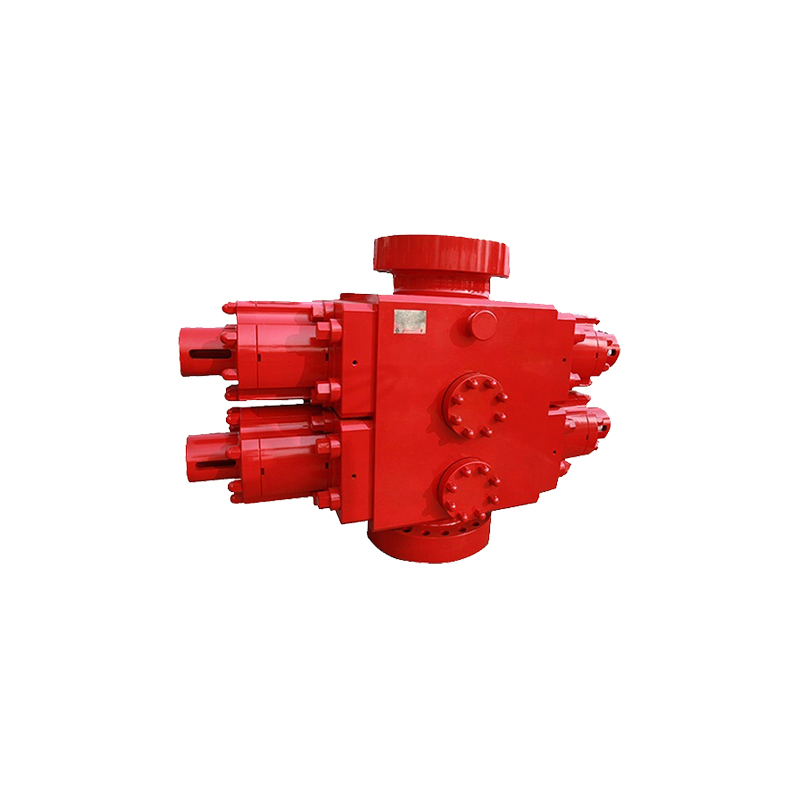

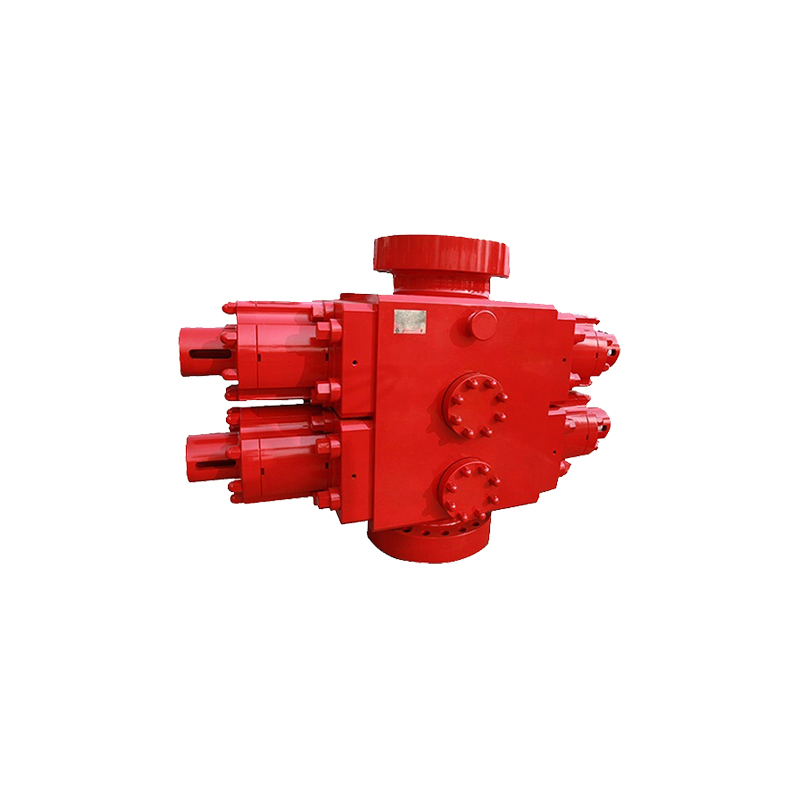

A sucker rod blowout preventer (BOP) is a critical safety device used in oil and gas drilling operations. This article aims to provide an in-depth understanding of sucker rod BOPs, their importance, components, functioning, and benefits in ensuring the safety and integrity of oil and gas wells.

I. Introduction

Sucker rod BOPs are specialized equipment designed to prevent the uncontrolled release of fluids, such as oil, gas, and drilling mud, during well intervention activities. They play a crucial role in maintaining the wellbore integrity and preventing blowouts, which can have catastrophic consequences.

II. Importance of Sucker Rod BOPs

Sucker rod BOPs serve several important purposes in oil and gas operations:

A. Well control and safety

The primary function of a sucker rod BOP is to control the flow of fluids in the wellbore and prevent blowouts. By sealing the wellbore and providing a barrier against the release of fluids under high pressure, BOPs protect workers, equipment, and the environment from potential hazards.

B. Pressure containment

Sucker rod BOPs are designed to withstand high pressures encountered during drilling, well completion, and intervention activities. They provide a reliable means of containing wellbore pressures and preventing the uncontrolled release of hydrocarbons.

C. Equipment protection

In addition to well control, sucker rod BOP protect drilling and production equipment from damage caused by fluid surges, kicks, or other unforeseen events. By quickly shutting off the flow path, BOPs safeguard valuable equipment and minimize costly downtime.

III. Components of Sucker Rod BOPs

Sucker rod BOPs consist of several essential components that work together to ensure effective well control:

A. Blowout Preventer Head

The blowout preventer head serves as the main housing for the BOP stack and provides support for other components. It contains the necessary control systems, such as hydraulic or manual actuators, to operate the BOP.

B. Ram Assemblies

Ram assemblies are critical sealing elements that can close around sucker rods, casing, or other tubular components in the wellbore. They create a reliable barrier to stop the flow of fluids in an emergency or when performing maintenance operations.

C. Annular Preventer

An annular preventer is a flexible sealing element that can be expanded or contracted to seal different sizes of sucker rods or casing. It provides a versatile sealing solution and is often used in conjunction with ram assemblies for effective well control.

D. Control System

The control system of a sucker rod BOP consists of hydraulic or manual valves, gauges, and associated equipment. It allows operators to control the opening, closing, and sealing of the ram assemblies or annular preventer as required.

E. Hydraulic Power Unit

A hydraulic power unit supplies the necessary hydraulic pressure to operate the BOP components. It comprises hydraulic pumps, accumulators, control valves, and other auxiliary equipment.

IV. Functioning of Sucker Rod BOPs

Sucker rod BOPs are activated in response to various wellbore conditions or operational requirements. The typical functioning of a sucker rod BOP involves the following steps:

A. Activation

When an emergency situation arises or routine maintenance needs to be performed, the BOP is activated by hydraulic or manual controls. The control system sends the appropriate signals to close the ram assemblies or expand the annular preventer.

B. Sealing and Pressure Control

Upon activation, the ram assemblies close around the sucker rods or other tubular components, forming a seal. This prevents the flow of fluids and maintains pressure control in the wellbore. The annular preventer can also be engaged to provide additional sealing if required.

C. Monitoring and Maintenance

Throughout the operation, the pressure and status of the BOP are continuously monitored to ensure proper functioning. Regular inspections and maintenance activities are performed to keep the BOP in optimal condition and ready for future use.

V. Benefits of Sucker Rod BOPs

Sucker rod BOPs offer several significant benefits to oil and gas operations:

A. Enhanced safety

The primary benefit of sucker rod BOPs is the enhanced safety they provide to workers, the environment, and equipment. By preventing blowouts and uncontrolled fluid releases, BOPs mitigate potential hazards and reduce the risk of accidents.

B. Regulatory compliance

Sucker rod BOPs are a regulatory requirement in many jurisdictions. Compliance with these regulations ensures that drilling and production activities meet the necessary safety standards, reducing legal and financial liabilities.

C. Protection of investments

Investing in sucker rod BOPs protects valuable drilling and production equipment from damage. By preventing catastrophic events, BOPs minimize downtime and costly repairs, ensuring operational continuity and preserving investments.

D. Environmental stewardship

Sucker rod BOPs contribute to environmental stewardship by preventing the release of hydrocarbons into the environment. Their use demonstrates a commitment to responsible drilling practices and minimizes the ecological impact of oil and gas operations.

VI. Conclusion

Sucker rod BOPs play a vital role in ensuring the safety, integrity, and regulatory compliance of oil and gas wells. By effectively controlling fluid flow, containing pressures, and protecting equipment, these essential devices mitigate the risk of blowouts and safeguard workers, the environment, and investments. Sucker rod BOPs are an integral part of responsible oil and gas operations, reflecting the industry's commitment to safety and environmental stewardship.

Comments

Please Join Us to post.

0