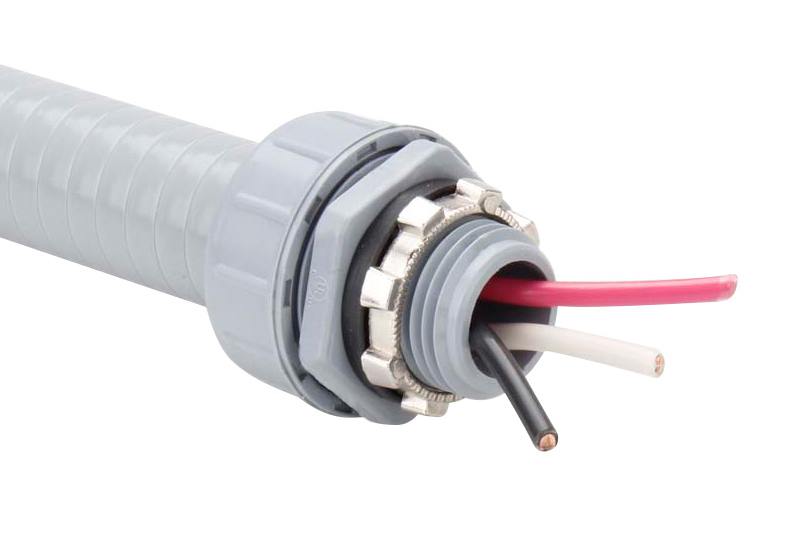

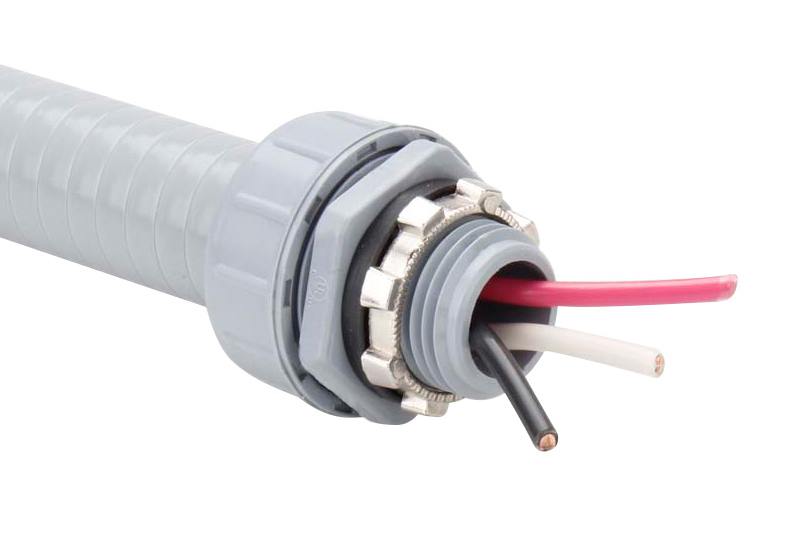

Non-metallic flexible conduit fittings are essential components in electrical installations, providing a versatile and reliable solution for protecting and routing electrical wires. In this comprehensive article, we will explore the features, benefits, and applications of non-metallic flexible conduit fittings. Whether you are an electrician, contractor, or someone interested in electrical systems, this article will provide valuable insights into the advantages of using non-metallic flexible conduit fittings in various installations.

1. Understanding Non-Metallic Flexible Conduit Fittings

Non-metallic flexible conduit fittings, also known as plastic conduit fittings, are designed to join and secure non-metallic flexible conduits, which are commonly made from PVC (polyvinyl chloride) or other thermoplastic materials. These fittings provide a reliable connection, offering flexibility and protection to the electrical wiring.

2. Advantages of Non-Metallic Flexible Conduit Fittings

2.1 Corrosion Resistance

One of the significant advantages of non-metallic flexible conduit fittings is their excellent resistance to corrosion. Unlike metallic fittings, which may deteriorate over time when exposed to moisture or corrosive environments, non-metallic fittings are highly durable and do not rust or degrade. This corrosion resistance ensures long-term reliability and reduces the need for frequent replacements or repairs.

2.2 Flexibility and Ease of Installation

Non-metallic flexible conduit fittings are designed to be highly flexible, allowing for easy installation in tight or complex spaces. The fittings can be bent, twisted, or manipulated to accommodate various installation requirements, making them suitable for both residential and commercial projects. This flexibility streamlines the installation process and reduces labor time and costs.

2.3 Lightweight and Non-Conductive

Non-metallic flexible conduit fittings are lightweight, which makes handling and installation more manageable. Additionally, as they are made from non-conductive materials like PVC, they provide an extra layer of safety by insulating electrical wires, minimizing the risk of electrical shocks or short circuits.

2.4 Chemical and UV Resistance

Non-metallic conduit fittings offer resistance to a wide range of chemicals, including acids, alkalis, and solvents. This feature makes them suitable for installations in industrial environments where exposure to corrosive substances is common. Moreover, non-metallic fittings are also UV resistant, ensuring their durability and performance even when exposed to sunlight or outdoor conditions.

3. Applications of Non-Metallic Flexible Conduit Fittings

Non-metallic flexible conduit fittings find applications in various electrical installations. Here are some common examples:

3.1 Residential Wiring

Non-metallic conduit fittings are widely used in residential wiring projects, including new constructions, renovations, or electrical system upgrades. They provide a safe and reliable solution for routing and protecting electrical wires in residential settings, such as homes, apartments, or condominiums.

3.2 Commercial and Industrial Buildings

Non-metallic conduit fittings are equally suitable for commercial and industrial applications. They are commonly used in office buildings, retail spaces, factories, and warehouses, where electrical installations require flexibility, corrosion resistance, and ease of maintenance. These fittings can accommodate the wiring needs of various systems, including lighting, power distribution, and communication networks.

3.3 Outdoor Installations

Non-metallic flexible conduit fittings are an excellent choice for outdoor electrical installations, such as landscape lighting, garden irrigation systems, or outdoor signage. The fittings' resistance to moisture, UV rays, and harsh weather conditions ensures the longevity and reliability of the electrical connections, even when exposed to the elements.

3.4 Data Centers and IT Facilities

Data centers and IT facilities require precise and reliable electrical installations to support critical equipment and networks. Liquid Tight Non-metallic conduit fittings offer a suitable solution for organizing and protecting the intricate wiring systems within these facilities. Their non-conductive nature and resistance to chemicals provide an added layer of safety and ensure the integrity of the electrical infrastructure.

Conclusion

Non-metallic flexible conduit fittings offer a versatile and reliable solution for protecting and routing electrical wires in various installations. Their corrosion resistance, flexibility, ease of installation, lightweight nature, and resistance to chemicals and UV rays make them an ideal choice for residential, commercial, industrial, and outdoor applications. By incorporating non-metallic flexible conduit fittings in your electrical projects, you can ensure the safety, durability, and efficiency of your electrical systems.

Comments

Please Join Us to post.

0