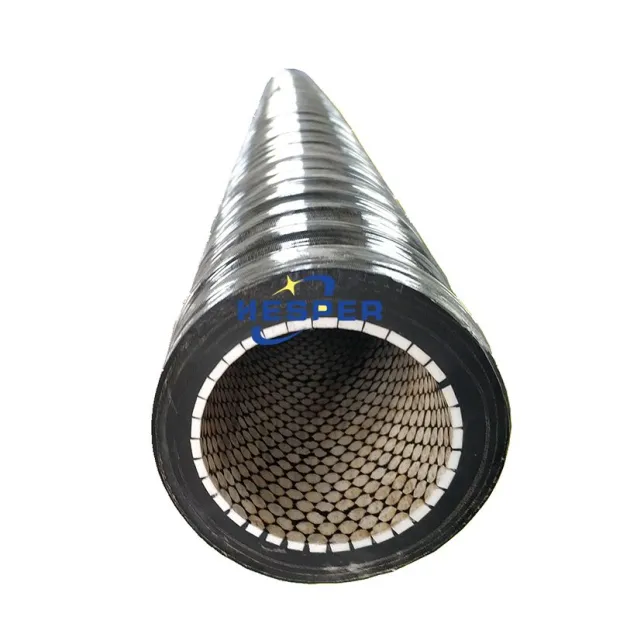

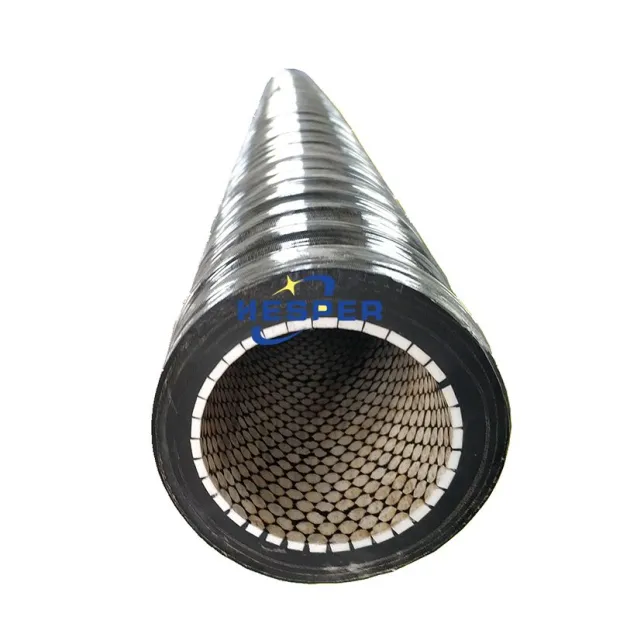

Ceramic lined rubber hoses are specialized pieces of equipment designed to handle abrasive materials and corrosive fluids in various industrial applications. These hoses combine the flexibility and durability of rubber with the abrasion and corrosion resistance of ceramics, offering several advantages over traditional rubber hoses. In this article, we will explore the numerous benefits of ceramic lined rubber hoses.

1. Abrasion Resistance: One of the primary advantages of ceramic lined rubber hoses is their exceptional resistance to abrasion. The ceramic lining protects the inner surface of the hose from wear and tear caused by abrasive materials such as sand, gravel, ores, and slurries. This ensures prolonged hose life and reduces the need for frequent replacements, saving both time and money for industries handling abrasive substances.

2. Corrosion Resistance: Ceramic lined rubber hoses are also highly resistant to corrosion, making them suitable for transporting corrosive fluids such as acids, alkalis, and chemicals. The ceramic lining acts as a barrier, preventing the rubber from coming into contact with corrosive agents and preserving the integrity of the hose over time. This corrosion resistance extends the service life of the hose and minimizes the risk of leaks or failures.

3. Temperature Resistance: These hoses exhibit excellent temperature resistance, allowing them to withstand extreme operating conditions. The rubber material provides flexibility and resilience, while the ceramic lining offers thermal stability, enabling the hose to handle both high and low temperatures without compromising performance. This makes ceramic rubber hoses suitable for use in a wide range of industries, including mining, steel production, power generation, and chemical processing.

4. Flexibility: Despite their robust construction, ceramic lined rubber hoses remain flexible and easy to handle, allowing for convenient installation and maneuverability in industrial settings. Unlike rigid piping systems, which may require complex fittings and joints, these hoses can be bent and twisted to accommodate various configurations and spatial constraints. This flexibility simplifies the installation process and reduces the need for additional components, contributing to overall cost savings.

Explore more:Upgrade Your Boat with Durable UHMW-PE Fender Panels and Custom Sill SolutionsMaximize Efficiency with Oem Hot Sale Pp Extrusion Plate - A Cost-effective Solution!New Meaning of Longya: The Ultimate Vocal Synthesizer RevolutionizedAre Longya voice banks the future?Ultimate Guide to Ultra High Molecular Weight Polyethylene Wear-Resistant PlateThe Ultimate Guide to Custom Injection MoldingTop 5 Plastic CNC Processing Services TrendsHow to Source Quality OEM Injection Molded Plastic Parts

5. Reduced Maintenance: Thanks to their superior abrasion and corrosion resistance, ceramic lined rubber hoses require minimal maintenance compared to conventional hoses. They are less prone to damage and deterioration, reducing the frequency of inspections and repairs. This not only lowers maintenance costs but also minimizes downtime and production interruptions, enhancing overall operational efficiency.

6. Increased Efficiency: By minimizing wear and tear, ceramic lined rubber hoses help maintain consistent flow rates and performance levels, leading to increased efficiency in industrial processes. They facilitate the smooth transfer of materials without clogging or blockages, ensuring optimal productivity and throughput. This improved efficiency translates into higher production yields and greater profitability for businesses utilizing these hoses.

7. Versatility: Ceramic lined rubber hoses are highly versatile and can be customized to meet specific application requirements. They come in various sizes, lengths, and configurations to suit different operating conditions and fluid handling needs. Additionally, they can be equipped with additional features such as flanges, couplings, and fittings for seamless integration into existing piping systems. This versatility makes ceramic lined rubber hoses a preferred choice for diverse industrial applications.

In conclusion, Industrial ceramic lined rubber hoses offer numerous advantages over traditional hoses, including superior abrasion and corrosion resistance, temperature resistance, flexibility, reduced maintenance, increased efficiency, and versatility. These qualities make them indispensable in industries where the transportation of abrasive or corrosive fluids is commonplace. By investing in ceramic lined rubber hoses, businesses can enhance operational reliability, minimize downtime, and improve overall profitability.

Explore more:Ultimate Guide to UPE Wear-Resisting Plates10 Questions You Should Know About UPE Ultra High Molecular Weight Polyethylene Wear-Resisting PlateHydraulic Hose Weeping - Topics | Noria Message BoardsUltimate Guide to Metal Corrugated Compensator for Oil & Gas PipelinesHow to Choose Dredge Suction Hose: A Comprehensive GuideCeramic Lined Rubber Hoses Market Overview: Market PotentialKey Questions to Ask When Ordering ODM Resin Hose Exporter

Comments

Please Join Us to post.

0